OUR PROJECTS

Steps to Success

Over the years, Filtec (LSE) has provided our customers with various clean solutions and added success value to their businesses. Equipped with the know-hows of developing appropriate solutions and coordinating with our partners, our competent LSE team has cultivated strong relationships with our partners by proving that we are a brand you can truly rely on.

We are proud to share some of the successful projects we have added to our achievements.

We are proud to share some of the successful projects we have added to our achievements.

TO IMPROVE EFFICIENCY, CLEANLINESS AND EXTEND MAINTENANCE INTERVAL FOR AN END USER WITH A FLEET OF DAF TRUCKS

Problem:

Current FW separator gets clogged quickly (within 2 months) and customer has to send their trucks for maintenance more frequently – resulting in greater downtime. Customer is also worried that the current pre-filter is not optimized for biodiesel water separation.

Location:

Customer’s own workshop

Country:

West Malaysia

Outcome:

Maintenance schedule extended to 6 months/100,000KM and entire fleet is fitted with our fuel water separator solution. Customer feels secure that once higher levels of biodiesel (B20/B30) are introduced by the government, he will not need to make any modifications or replacements as our elements are B100 capable.

Problem:

According to the water discharge standards set forth by the Public Utilities Board, the silty water generated from the building site have to be treated to <50 mg/L of TSS before discharge public drainage system

Solution:

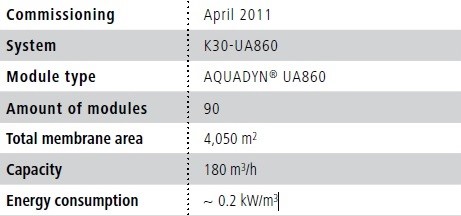

An effective Erosion Control Measure (ECM) of Klar-30 System consisting of 90pcs AQUADYN® UA860 was installed at a building site to treat the storm water before discharging it to the public drainage system

Location:

Construction site

Country:

Singapore

Outcome:

From a feed water of TSS 4000mg/L, the output effluent manage to achieve a targeted level of less than 1mg/L of TSS which meet the PUB discharge standard

Plant Design:

Problem:

Surface water contain microorganisms and suspended solids from water that make it unsafe for consumption as drinking water

Solution:

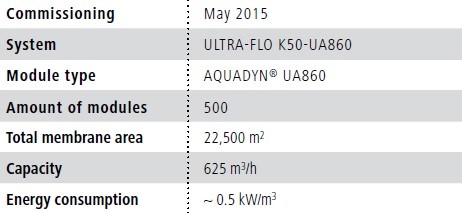

The water treatment plant is equipped with 500 AQUADYN® UA860 ultrafiltration modules by MICRODYN-NADIR and has a total membrane area of 22,500 m2. This will effectively reduce the microorganisms and suspended solids from water. The AQUADYN® UA (PAN) modules is superior in its hydrophilic property compared to most other polymeric materials. The enhanced hydrophilic property improves the wettability and reduces operating pressure. Additionally, it makes the membrane more resistant to fouling; resulting in less cleaning cycles and reduced chemical usage.

Location:

Kalibo

Country:

Philippines

Outcome:

The water treatment plant is able to meets and fulfils the needs of the municipal water districts vision to install a state-of-the-art water treatment system in order to supply Kalibo Water District with safe and continuous water

Plant Design: